ECOFILL’s Spacer bar covers

Ecofill offers a complete range of various styles of spacer bar covers.

- Operating temperatures up to 500 °C / 950F.

- Fabricated to customer specifications.

- Reducing quantity of damaged profiles during heat treat process.

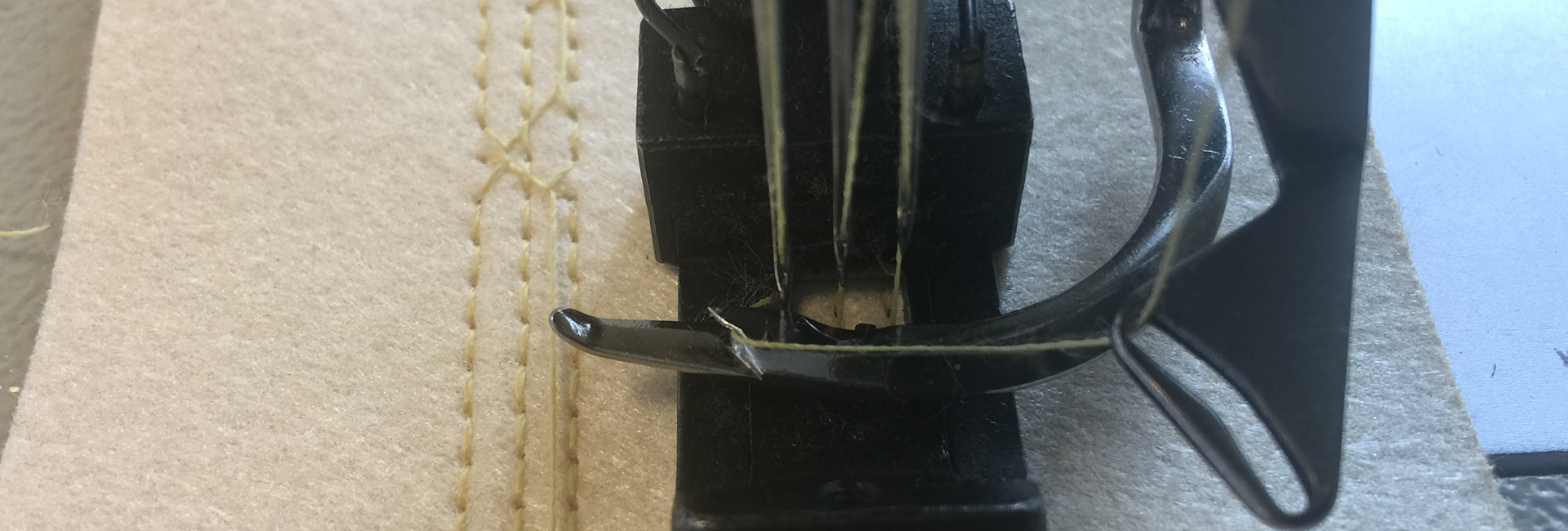

- From welded seams to superior stitching; seamless flatlock, giving superior performance in all applications.

- Shrink sleeves, locking the spacer sleeves in place on spacer bar to allow proper operation of automatic stacking equipment.

- Shrink material eliminates sagging and slipping.

- Custom fabricated.

- Materials most often used: Polyesther, Trevira, PPS, Nomex, Kevlar, Zylon, Glass

Impregnation:

All ECOFILL/HONESTY Needle felt products are available with resin impregnation, not leaving stains on hot extruded aluminum profiles! The resin impregnation enhances the durability of the roller sleeves, belts, pads and makes it more stiff. The hardness of the roller sleeve can be adjusted by the concentration of the resin together with the amount of resin treatment cycles of the felt products. Next to a higher durability another advantage of resin impregnation is that aluminum swarf and or dirt does not stick into the felt.

Spacer bar covers range

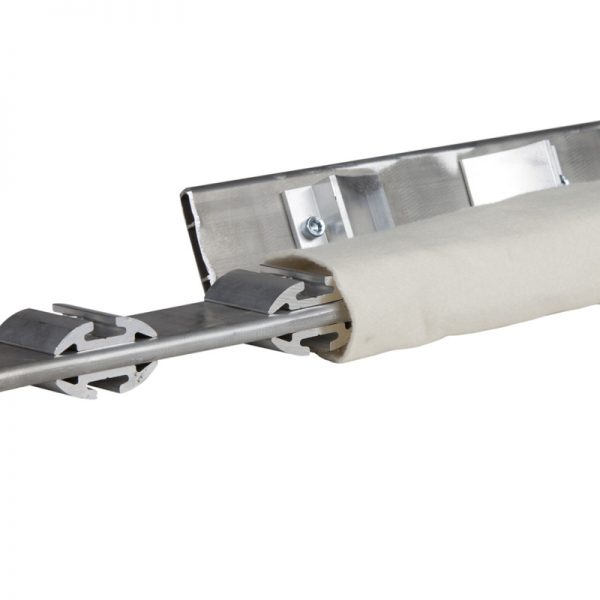

Polyester endless woven shrink spacer sleeve

High tenacity endless Polyesther sleeve.

- Operating Temperature : 185- 220 °C/ 365-428 F

- Shrickage: Max 8%

On request cut to length.

Most common sizes are available from stock. Other sizes can me supplied at a minimum of 1000 meters/ yards per lot.

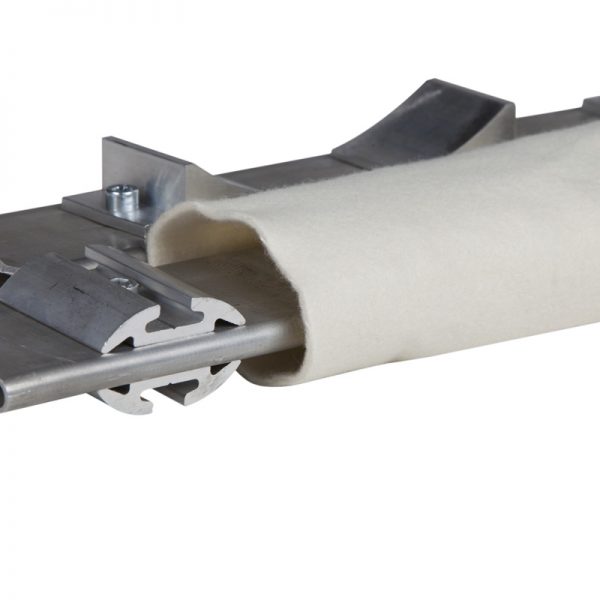

Trevira Polyester endless spacer sleeve

High tenacity endless Trevira Polyester sleeve.

- Operating Temperature : 185- 220 °C/ 365-428 F

- Shrickage: Max 8%

- High density for longer lifetime

- Better cushioning effect compared to standard Polyester endless spacer sleeve.

On request cut to length.

Most common sizes are available from stock. Other sizes can me supplied at a minimum of 1000 meters/ yards per lot.

Endless glass spacer sleeve

Endless glass spacer sleeve

- Operating Temperature : 700 °C/ 1300 F

- Shrickage: 0 %

Most common sizes are available from stock. Other sizes can me supplied at a minimum of 1000 meters/ yards per lot.

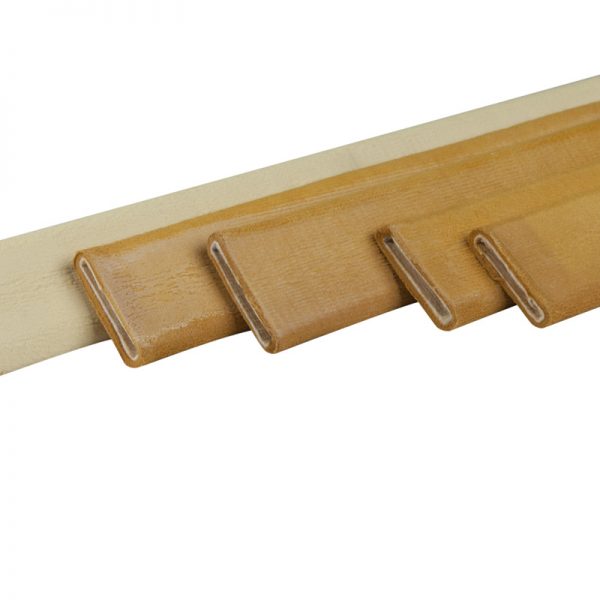

Polyester Needlefelt Spacer

Polyester needlefelt sleeve.

- Operating Temperature : 185- 220 °C/ 365-428 F

- Shrickage: Max 8%

- Needlefelt for improved cushioning effect

- Better cushioning effect compared to standard endless knitted Polyester fabric.

On request cut to length.

All common sizes manufactured according to customer specification; including various stitching styles, sewing threads: meta-aramid, nomex, para-aramid, kevlar, PBO, PBO/Zylon, glass.

- Temperature resistance up to peaks of 1020 F / 550 C

- Really seamless and endless

- Round needled

- Smooth homogenious felt surface (no woven patterns)

- High pore volume without any affinity to stick on the extruded aluminum profiles.

Special resin impregnations or hardening available for all roller cover dimensions.

Application area: initial zone, run out and pick-up; especially suitable for your waterquench or other moist environments.

Features:

-

Roller covers manufactured in Zoeterwoude / The Netherlands for high temperature (T650) application down to rubber / Synthetic or plastics Rollers for low temperature ranges from 240C down to -10C.

-

Extremely smooth & homogenious felt surface

-

Optimal thermal insulation properties

-

Antistatic optional

-

Wide product range for individual systems

-

Different wall thicknesses (3.5 up to 13 mm) for most common ID’s

-

Special resin treatment for heavy presses

-

Round needled, seamless